¶ Replacement of X-axis slider

¶ When to Replace

The copper block is severely worn.

¶ Replace Guide

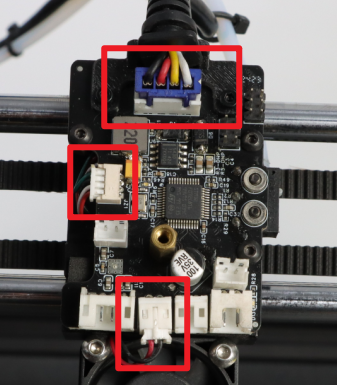

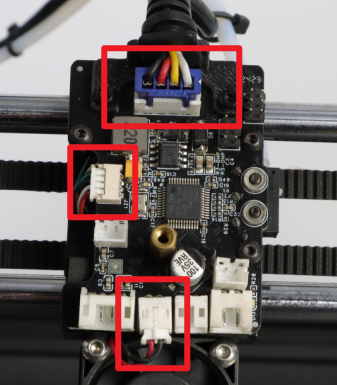

- After disassembly the toolhead, take out the terminals of the strain gauge, the 3015 fan, and the communication terminal of the motherboard.

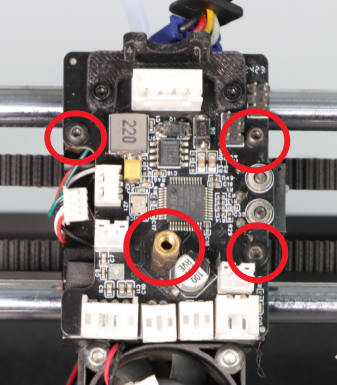

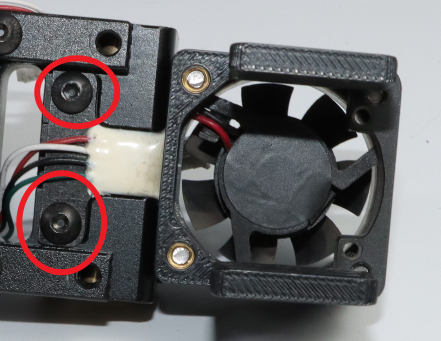

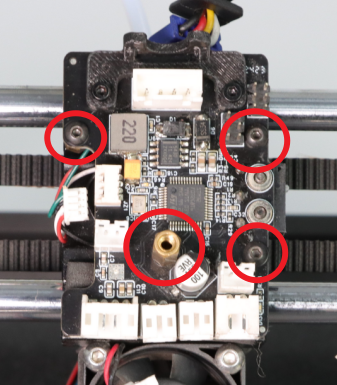

- Disassembly the screws and Copper pillar. Take out mainboard of toolhead.

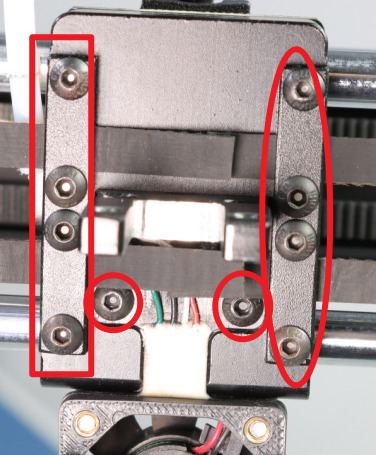

- Loosen the 10 screws at the bottom of the X-axis slider, remove the strain gauge and the two synchronous belt mounting plates.

- Loosen the screws of the XY motor, move the motor upwards, and release the synchronous belt.

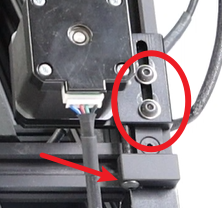

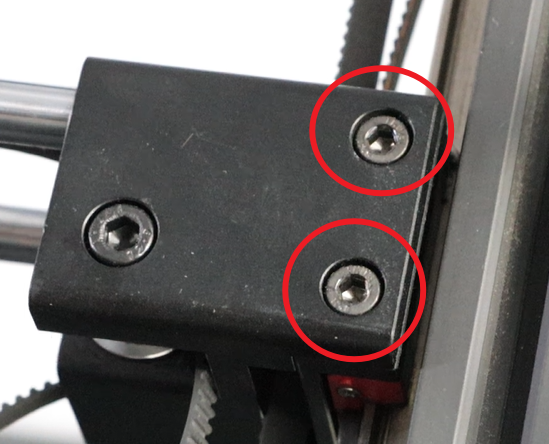

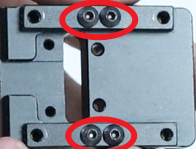

- Disassembly the 8 screws from the X-axis fixing blocks on both sides. The picture below shows the 2 screws on the front side of the right fixing block, and there are another 2 on the back side.

- Disassembly the entire X-axis from the Y-axis slider.

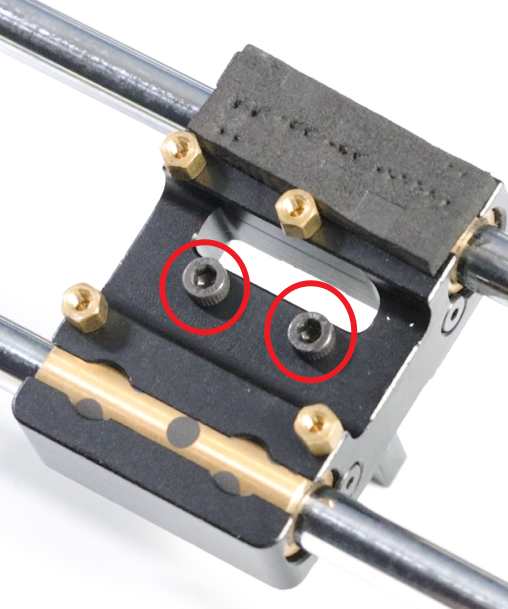

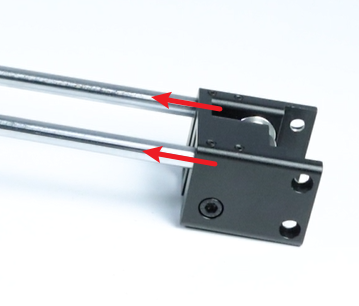

- Loosen the Set screw on the fixed block on one side of the X-axis, so that the optical axis and the fixed block are separated.

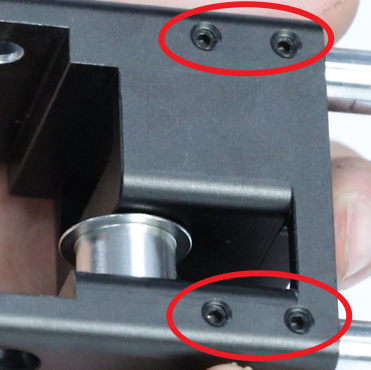

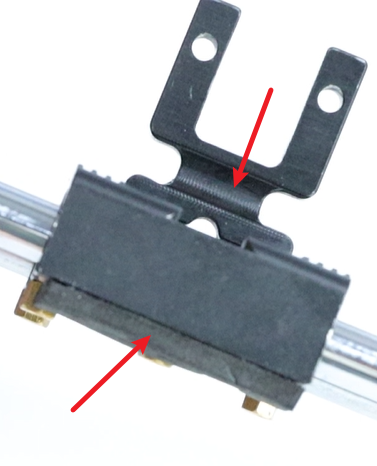

- Slide the X-axis slider out, remove the screws on the top, and detach the print head mounting block.

- Install the print head fixing block (2 M3×14 hexagonal screws for the nozzle) and 2 synchronous belt fixing plates (4 M3×8 hexagonal screws for the disc head) onto the new X-axis slider (pay attention to the orientation of the print head fixing block, with the grooved side facing the nozzle, and the side with cotton on the slider.)

- Disassembly e terminals on the strain gauge from the hole beneath the X-axis slider and place them aside. Then align the strain gauge with the slot at the bottom of the X-axis slider and lock it into two M3×4 head hexagonal screws (make sure the strain gauge does not shake after being tightened, otherwise there will be a malfunction when homing the Y-axis).

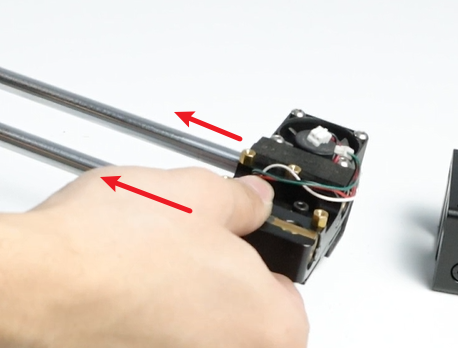

- Place the new X-axis slider onto the optical axis.

- Put the removed X-axis fixing block back onto the optical axis. After reinstallation, move the slider to check if it moves smoothly. You can make the slider move smoothly by rotating the optical axis or loosening the remaining two screws on the X-axis fixing block.

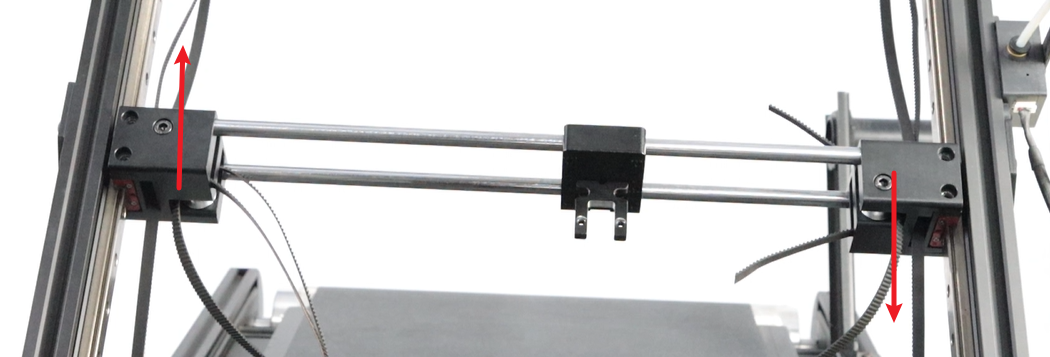

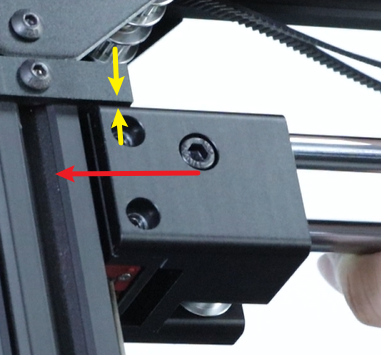

- Reinsert the entire X-axis into the Y-axis slider. Align the screw holes of the X-axis fixing block with the fixing holes of the Y-axis slider, then lock in the screws (8 M4×5 cup head hexagonal screws). At this point, do not tighten yet. Push the X-axis fixing block to both sides to make the X-axis fixing block tightly adhere to the Y-axis slider. Then move the X-axis to the top. Note that there should be no gap between the two fixing blocks and the upper part (as indicated by the yellow arrow in the picture). Press down on the bottom of the fixing block and then lock the screws (pay attention to the direction of the slider, the 3015 fan faces the conveyor belt).

Move the X-axis slider to check if it is smooth. If it is smooth, lock the base screws. If not, loosen the screws on the other side and then rotate the two optical axes. Then continue to move the X-axis slider until it becomes smooth. Finally, lock the Set screws.

Move the X-axis slider to check if it is smooth. If it is smooth, lock the base screws. If not, loosen the screws on the other side and then rotate the two optical axes. Then continue to move the X-axis slider until it becomes smooth. Finally, lock the Set screws.

- Reinstall the locking screws (M2.5×4 flat-head hexagonal screws, 3 pieces) on the print head motherboard and the copper posts (M2.5×12 + 4).

- Reference Replacement of the synchronous belt on the x,y axis, After arranging the synchronous belt properly, insert it into the synchronous belt fixing slot and lock it with screws (4 M3×5 head hexagonal screws). Tighten the loosened screws on the XY motor, and straighten the synchronous belt.

- Insert the strain gauge terminals, the 3015 fan terminals and the mainboard line terminals.

Assemble the toolhead back together, After turning on the machine, click the “Auto Leveling” button.